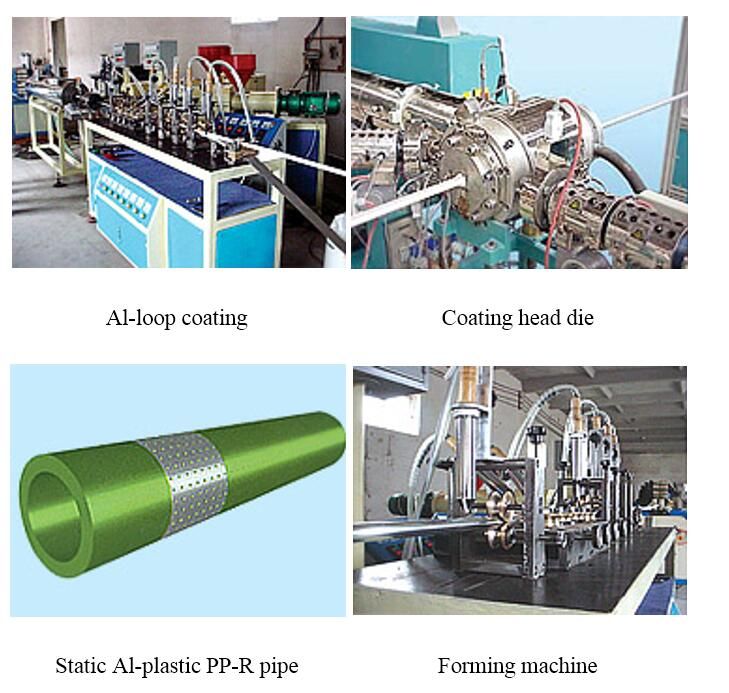

Pipe Production Line

Aluminum-plastic composite pipe production line

Technical parameter:

Modle | Diam. range of pipe | Product speed (m/min) | total install (kW) | Overall dim. L×W×H(m) |

SJLS-30B | φ16-φ32 | 6-20 | 185 | 53×5×2.5 |

SJLS-60B | φ16-φ63 | 3-18 | 198 | 59×5×2.5 |

Product description:

Appearing on the market, there are three plastic composite pipe: 1, PE / AL / PE (outer layer of polyethylene); 2, PE / AL / PEX (crosslinked polyethylene inner layer, outer layer of polyethylene); 3 , PEX / AL / PEX (crosslinked polyethylene inner and outer layers are the central layer are aluminum layer).

Aluminum-plastic composite pipe has good insulation properties, corrosion inside and outside the wall is not easy, due to smooth inner wall, the fluid resistance is small; and because to bend, so easy installation and construction. As water pipes, aluminum plastic composite pipe has sufficient strength.

Two kind welding process:

1. ultrasonic lap seam welding, co-extrusion forming.

2. butt-joint argon-arc welding, welding seam close-gained and smooth.

3. Controlling center adopting computer control system of Austria B&R company programmable computer.

4. Long-distance closed loop control automatically the process of the speed of extruding and hauling, temperature and product diameter.

utomatically the process of the speed of extruding and hauling, temperature and product diameter.