Xindacheng events

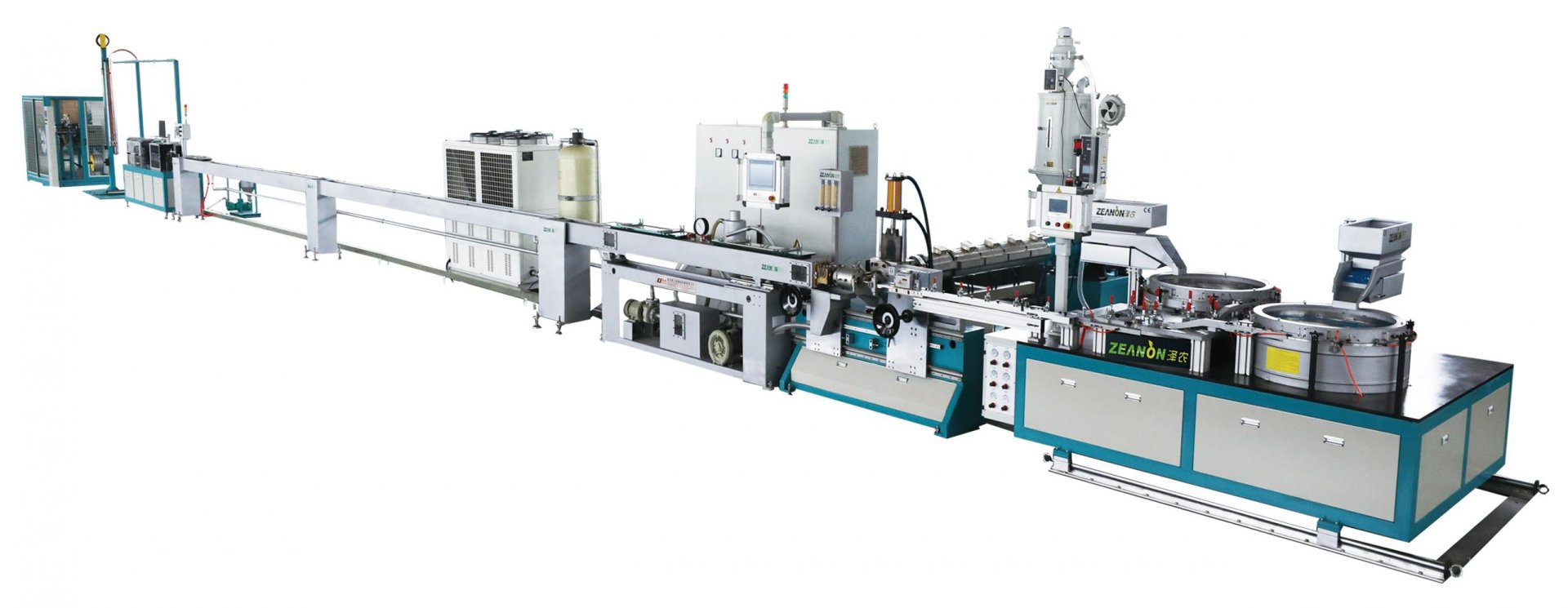

Customers from domestic and Russia visit and make the orders High speed flat drip irrigation pipe production line

On August 7th, Russian customers and local customers in Qingdao were invited to visit and inspect XDC-300B high-speed drip irrigation pipe production line (350m/min) produced by XinDacheng Company. After the inspection, customers fully affirmed our company's modern management and product quality, and proposed a purchase plan to complete the order on the same day.

XDC-300B high-speed drip irrigation pipe production line (350m/min) produced by XinDacheng Company with a high degree of automation, fast production speed, stable production as the main advantages, has attracted the favor of many customers at home and abroad, and has been unanimously praised.

Main technical parameters

Name | Diameter | Speed | Dripper spacing |

300B high speed drip irrigation pipe production line | φ12、16、20、25mm | 350m/min | 100-1000mm |

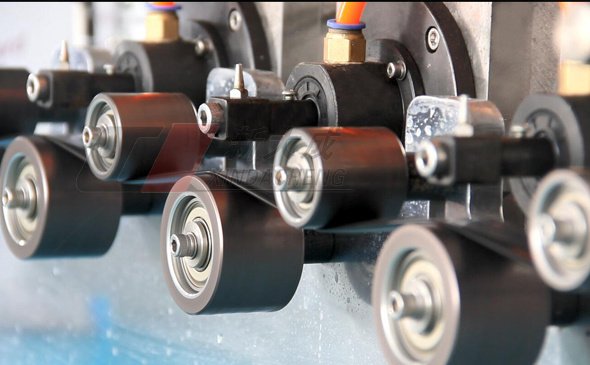

Advantage 1

※Two automatic screening and identification devices can automatically eliminate unqualified drops to ensure 100% pass rate.

※Equipped with drip storage device.

※Number of drips: 3000 / min.

Advantage 2

※Drip conveyor, paste, head cooling water tank is designed on a line guide, can be 350 meters/minute high-speed production of 0.12-0.9mm wall thickness drip irrigation pipe.

Advantage 3

※30% Optional servo drive main motor, maintenance-free, 30% power saving.

※Low temperature plasticizing concept, suitable for different countries and brands of raw materials.

※Co-extruded: ABA or AB.

Advantage 4

※Punching speed 4000 times/min.

※Single punch, double punch, three punch and four punch machines are available as required.

※According to the different wall thickness can choose mechanical punching and wind pen rotary punching.

※Built-in missing identification alarm system and dropper spacing deviation identification alarm system.

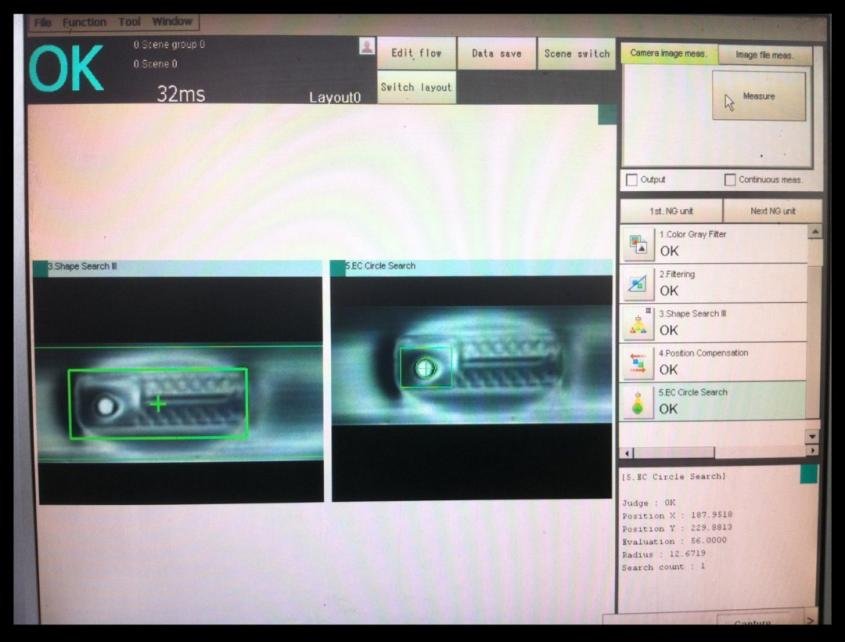

Advantage 5

※Advanced operation control screen, using (German or Japanese brands), can set the punching range.

※An online imaging analysis system monitors the state of each hole and performs imaging analysis.

※Automatic alarm and storage information function, and can be linked with downstream equipment.

Advantage 6

※Double station automatic winding and rewinding function, driven by servo motor.

※PLC control automatically complete wiring, winding, cutting, changing, meter counting and cutting.

※Fully enclosed safety protection structure.

※Take-up speed 350m/min.

※With a locking device, the winding process will not loose.

※With a locking device, the winding process will not loose.